Unraveling the Wonders of Multilayer PCBs: A Deep Dive into Advanced Circuitry

In the fast-paced world of electronics, where innovation is the driving force, the demand for compact, efficient, and high-performance electronic devices is ever-increasing. At the heart of these devices lies a crucial component that plays a pivotal role in their functionality – the Printed Circuit Board (PCB). As technology advances, so does the complexity of electronic circuits, giving rise to the prominence of Multilayer PCBs. In this blog, we will delve into the intricacies of Multilayer PCBs, exploring their structure, benefits, and applications in the modern world of electronics.

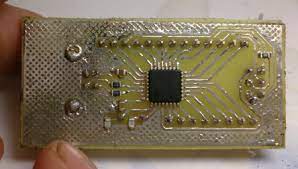

Understanding Multilayer PCBs: Traditional single-layer and double-layer PCBs have their limitations in terms of circuit complexity and miniaturization. Multilayer PCBs address these limitations by incorporating multiple layers of conductive material separated by insulating layers, typically made of a substrate material like fiberglass-reinforced epoxy. The conductive layers are interconnected through vias, allowing for a more intricate and compact circuit design.

Structure of Multilayer PCBs:

- Core Layer: The core layer serves as the primary structural backbone, providing mechanical strength to the PCB. It is typically made of a non-conductive material like FR-4 (Flame Retardant 4), a popular choice for its excellent balance of electrical and thermal properties.

- Conductive Layers: Sandwiched between the core layers are conductive layers, usually made of copper. These layers form the circuitry and are etched to create the desired electrical paths. The number of conductive layers can vary, with common configurations being 4-layer, 6-layer, 8-layer, and even more complex designs.

- Prepreg Layers: Prepreg layers are sheets of fiberglass impregnated with uncured epoxy resin. These layers provide insulation between the conductive layers and are cured during the PCB manufacturing process to create a solid insulating material.

- Vias: Vias are small holes drilled through the PCB, connecting the conductive layers. They play a crucial role in facilitating the flow of signals between layers and are classified into two types: plated through-hole (PTH) vias and non-plated through-hole (NPTH) vias.

Benefits of Multilayer PCBs:

- Compact Design: Multilayer PCBs enable the integration of complex circuits in a compact space, making them ideal for applications where size is a critical factor.

- Improved Signal Integrity: The layered structure of Multilayer PCBs reduces signal interference and crosstalk, enhancing the overall signal integrity of the circuit.

- Increased Density: With more layers available for circuitry, Multilayer PCBs allow for higher component density, supporting the integration of advanced electronic components.

- Enhanced Reliability: The multiple layers provide redundancy, reducing the impact of a single-point failure and improving the overall reliability of the electronic device.

Applications of Multilayer PCBs:

- Consumer Electronics: From smartphones and laptops to smart TVs and wearables, Multilayer PCBs are widely used in consumer electronics to accommodate the complexity of modern features and functionalities.

- Medical Devices: The medical industry relies on Multilayer PCBs for applications such as diagnostic equipment, patient monitoring devices, and medical imaging systems.

- Communications Systems: Telecommunications equipment, routers, and networking devices leverage Multilayer PCBs to support the high-speed data transfer and complex signal processing requirements.

- Automotive Electronics: In the automotive sector, Multilayer PCBs are employed in advanced driver assistance systems (ADAS), engine control units (ECUs), and infotainment systems.

Conclusion: As the world of electronics continues to evolve, Multilayer PCBs stand at the forefront of technological advancements, enabling the development of more sophisticated and compact electronic devices. Their versatility, reliability, and enhanced performance make them a cornerstone in various industries, driving innovation and pushing the boundaries of what is possible in the realm of electronic circuitry.