Unveiling the Advancements: A Deep Dive into HDI PCB Technology

In the fast-paced world of electronics, technological innovations continue to shape the landscape of printed circuit boards (PCBs). One such advancement that has gained significant attention is High-Density Interconnect (HDI) PCB technology. HDI PCBs represent a leap forward in design and functionality, offering a myriad of benefits that cater to the demands of modern electronic devices.

Understanding HDI PCBs:

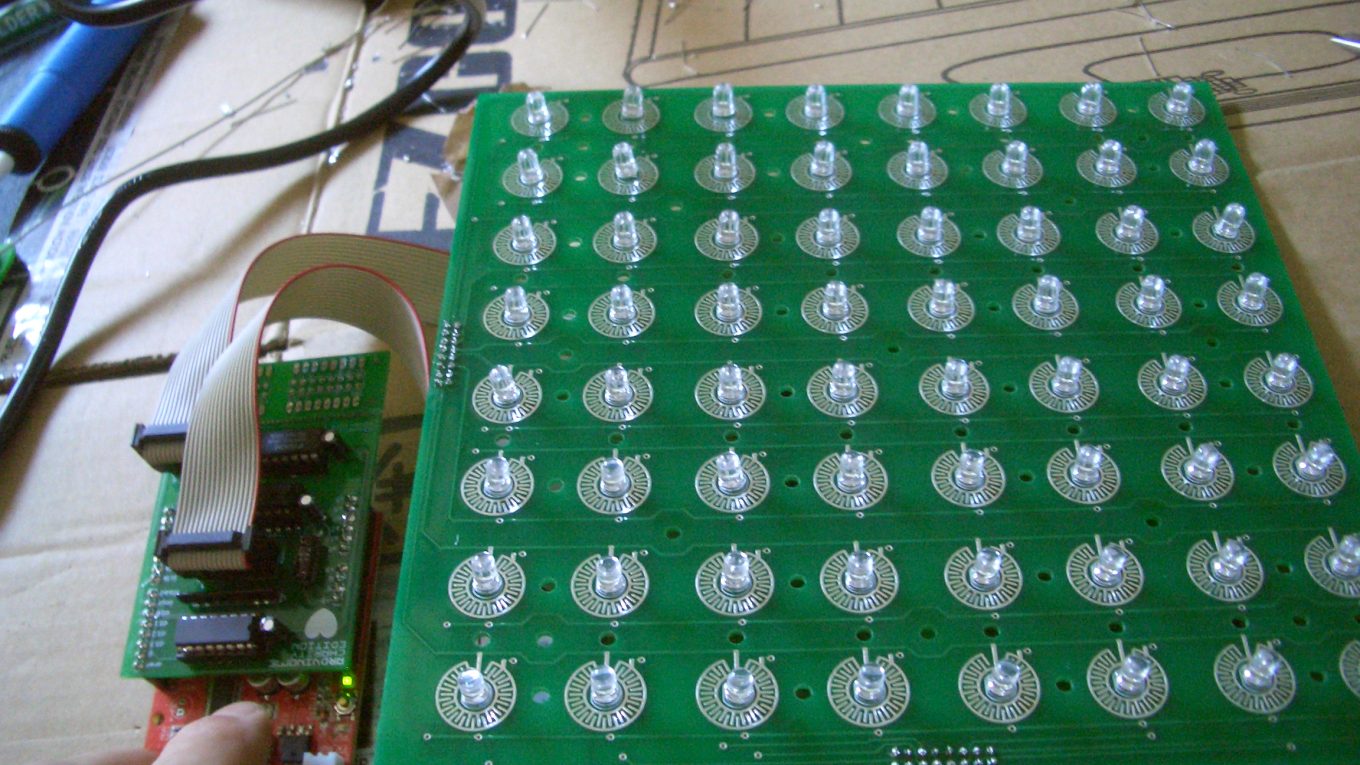

HDI PCBs are a type of printed circuit board that boasts a higher density of components and interconnections than traditional PCBs. These boards are designed to accommodate smaller and more intricate electronic devices, such as smartphones, tablets, and wearables. The key to HDI technology lies in the increased number of layers, finer traces, and smaller vias, allowing for the efficient integration of complex circuits in a compact space.

Key Features and Advantages:

- High Component Density: HDI PCBs excel in accommodating a greater number of components within a limited space. This is achieved by utilizing advanced manufacturing techniques that allow for tighter component placement and smaller pitch sizes.

- Miniaturization: As electronic devices continue to shrink in size, the need for compact PCBs becomes imperative. HDI technology facilitates the miniaturization of electronic products, enabling manufacturers to produce smaller and lighter devices without compromising functionality.

- Improved Signal Integrity: The reduced size of traces and vias in HDI PCBs contributes to improved signal integrity. The shorter paths and minimized electromagnetic interference enhance the overall performance and reliability of the electronic system.

- Enhanced Thermal Management: With the increasing complexity of electronic designs, managing heat dissipation is crucial. HDI PCBs incorporate advanced materials and design principles to enhance thermal conductivity, ensuring that the electronic components operate within optimal temperature ranges.

- Increased Reliability: The intricate design and advanced manufacturing processes of HDI PCBs contribute to enhanced reliability. The minimized risk of signal distortion, reduced electromagnetic interference, and optimized thermal performance collectively result in a more robust and dependable electronic system.

Applications:

HDI PCBs find widespread applications across various industries, including telecommunications, automotive, medical devices, and consumer electronics. These boards have become indispensable in the production of high-performance and compact electronic devices, such as 5G equipment, advanced medical imaging devices, and the latest generation of smartphones.

Challenges and Future Outlook:

While HDI PCBs offer a plethora of advantages, they also pose challenges in terms of manufacturing complexity and cost. As the demand for smaller and more powerful electronic devices continues to rise, manufacturers are investing in research and development to overcome these challenges and make HDI technology more accessible.

In conclusion, High-Density Interconnect PCB technology represents a significant milestone in the evolution of electronic design. Its ability to pack more functionality into smaller spaces opens up new possibilities for innovation in various industries. As advancements in manufacturing processes continue, we can expect HDI PCBs to play a pivotal role in shaping the future of electronics, enabling the creation of even more compact and powerful devices.