Unveiling the Wonders of Aluminum PCBs: A Revolution in Electronics

In the ever-evolving world of electronics, innovation is the key to progress. One such groundbreaking advancement that has taken the industry by storm is the Aluminum Printed Circuit Board (PCB). This marvel of engineering has redefined the way electronic devices are designed, offering numerous benefits that contribute to enhanced performance, durability, and efficiency. In this blog, we will delve into the intricacies of Aluminum PCBs, exploring their features, applications, and the transformative impact they’ve had on electronic devices.

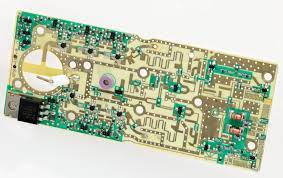

Understanding Aluminum PCBs: Traditional PCBs are typically constructed using materials like fiberglass or epoxy, but Aluminum PCBs break away from this convention by incorporating an aluminum base. The base layer, often made of aluminum alloy, provides a solid foundation for the circuitry and components. This departure from conventional materials brings forth a range of advantages that make Aluminum PCBs an attractive choice for various applications.

Key Features of Aluminum PCBs:

- Thermal Conductivity: One of the standout features of Aluminum PCBs is their exceptional thermal conductivity. Aluminum is an excellent heat conductor, allowing for efficient dissipation of heat generated during the operation of electronic components. This characteristic is especially crucial in high-power applications and devices where heat management is paramount.

- Durability and Mechanical Strength: The use of aluminum as the base material enhances the mechanical strength and durability of the PCB. This makes Aluminum PCBs more robust and resistant to mechanical stress, ensuring a longer lifespan for electronic devices.

- Lightweight: Despite its strength, aluminum is a lightweight material. This property is particularly advantageous in applications where weight is a critical factor, such as aerospace and automotive electronics.

- Electromagnetic Shielding: Aluminum PCBs also provide inherent electromagnetic interference (EMI) shielding. This shielding capability ensures that sensitive electronic components are protected from external interference, enhancing the overall reliability of the electronic system.

Applications of Aluminum PCBs:

- LED Lighting: The LED lighting industry has embraced Aluminum PCBs due to their excellent thermal performance. These boards effectively dissipate the heat generated by high-power LED components, extending the lifespan of the lighting fixtures.

- Power Supplies: Power supply units, which often generate significant heat during operation, benefit from the superior thermal conductivity of Aluminum PCBs. This makes them ideal for applications where efficient heat dissipation is crucial.

- Automotive Electronics: The automotive industry has adopted Aluminum PCBs in various electronic components, thanks to their lightweight design and ability to withstand the harsh conditions of automotive environments.

- Telecommunications: In the telecommunications sector, Aluminum PCBs are used in devices that require high-frequency performance and reliability, such as amplifiers and transmitters.

Conclusion: The introduction of Aluminum PCBs has ushered in a new era of possibilities for electronic design and manufacturing. Their unique combination of thermal conductivity, durability, and electromagnetic shielding has made them indispensable in various industries. As technology continues to advance, the role of Aluminum PCBs is likely to expand further, influencing the design and performance of electronic devices across the globe.