Mastering PCBA Test: Ensuring Quality and Reliability in Electronic Manufacturing

In the fast-paced world of electronic manufacturing, ensuring the quality and reliability of printed circuit board assemblies (PCBAs) is crucial for the success of any product. PCBAs are the heart of electronic devices, and defects or failures can lead to costly recalls, damaged reputations, and dissatisfied customers. This is where PCBA testing comes into play – a comprehensive process that guarantees the functionality and performance of electronic components. In this blog, we will explore the significance of PCBA testing, the different testing methods, and the role it plays in maintaining high-quality electronic products.

The Importance of PCBA Testing:

PCBA testing is an essential step in the electronic manufacturing process. It involves a series of checks and evaluations to ensure that each component on the printed circuit board is functioning correctly and meeting the required specifications. The primary objectives of PCBA testing include:

- Fault Detection:

- Identify defects in soldering, component placement, or any other manufacturing process to prevent faulty units from reaching the end-user.

- Quality Assurance:

- Ensure that each PCB assembly meets the specified quality standards and adheres to design specifications.

- Reliability Assessment:

- Evaluate the long-term reliability and performance of the PCBA under various operating conditions.

- Cost Reduction:

- Detecting and rectifying defects early in the manufacturing process helps reduce the overall cost by avoiding rework and minimizing the risk of product recalls.

Common PCBA Testing Methods:

- Automated Optical Inspection (AOI):

- AOI uses cameras and image recognition software to inspect the PCB for defects in soldering, component placement, and other visual issues. It is a fast and efficient method for detecting surface defects.

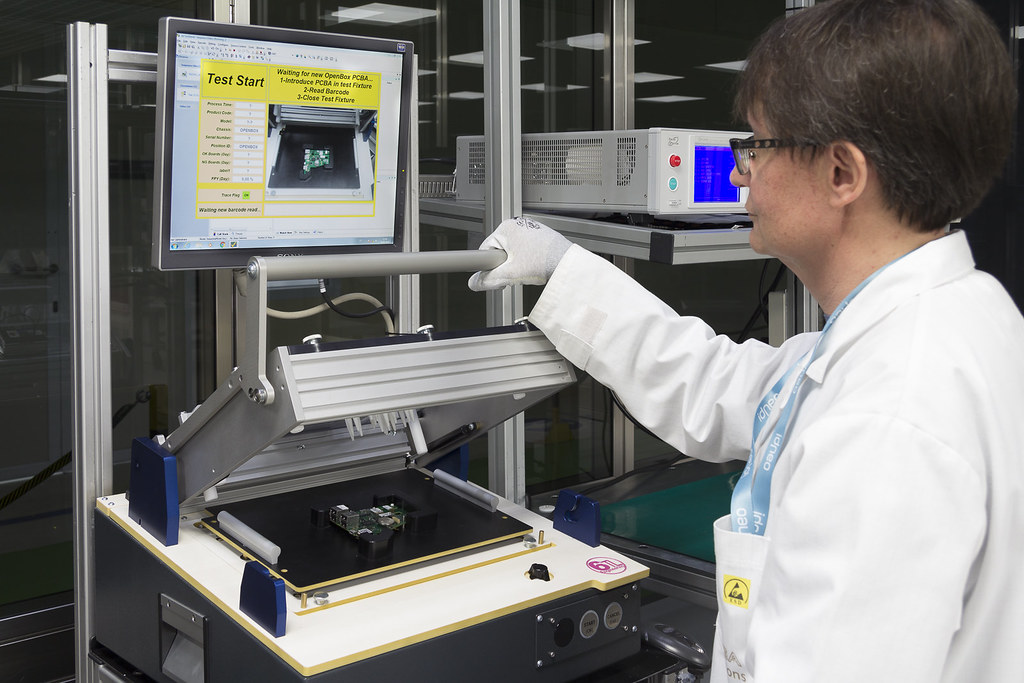

- In-Circuit Testing (ICT):

- ICT involves testing individual components and connections on the PCB using specialized test fixtures. It is effective in identifying component failures and ensuring proper functionality.

- Functional Testing:

- This method verifies that the PCBA performs its intended functions as specified in the design. It tests the entire circuit’s functionality rather than individual components.

- Boundary Scan Testing:

- Boundary scan testing checks the interconnects between integrated circuits on the PCB. It is particularly useful for identifying faults related to the connections between different components.

- X-ray Inspection:

- X-ray inspection is employed for inspecting hidden solder joints, ensuring that there are no internal defects that may affect the PCBA’s reliability.

Challenges in PCBA Testing:

While PCBA testing is crucial, it comes with its own set of challenges, including:

- Miniaturization:

- As electronic components become smaller and more densely packed, it becomes challenging to inspect and test them effectively.

- Complexity of Designs:

- Advanced and complex PCB designs make it difficult to ensure complete coverage during testing.

- Cost Constraints:

- Striking a balance between comprehensive testing and cost-effectiveness is a constant challenge in electronic manufacturing.

Conclusion:

In conclusion, PCBA testing plays a vital role in ensuring the quality, reliability, and functionality of electronic products. As technology continues to advance, the need for robust testing methods becomes even more critical. Manufacturers must invest in state-of-the-art testing equipment and methodologies to meet the ever-increasing demands for high-quality electronic components. By prioritizing PCBA testing, companies can build a reputation for producing reliable and defect-free products, ultimately contributing to their long-term success in the competitive electronics market.