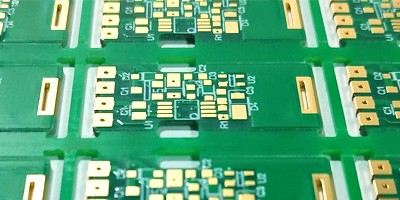

Navigating the PCB Landscape: Choosing the Right Supplier for Your Electronics Project

In the ever-evolving realm of electronics, printed circuit boards (PCBs) play a crucial role in connecting and powering devices. Whether you’re a hobbyist working on a small project or a business aiming to produce cutting-edge technology, selecting the right PCB supplier is a critical decision. This blog explores the factors to consider when choosing a PCB supplier and highlights the importance of finding a reliable partner for your electronics endeavors.

Understanding Your Needs:

Before diving into the world of PCB suppliers, it’s essential to have a clear understanding of your project’s requirements. Consider factors such as board size, layer count, material specifications, and production volume. Knowing your needs upfront will help you narrow down the list of potential suppliers and ensure a smoother selection process.

Reliability and Reputation:

One of the first things to look for in a PCB supplier is reliability. A reputable supplier should have a proven track record of delivering high-quality products on time. Research customer reviews, testimonials, and case studies to gauge the supplier’s reliability and customer satisfaction. Additionally, consider how long the supplier has been in the industry, as longevity often indicates stability and expertise.

Quality Assurance and Certifications:

Quality is paramount when it comes to PCBs, as even minor defects can lead to malfunctions in electronic devices. Ensure that your chosen supplier adheres to industry standards and certifications such as ISO 9001 and IPC-A-600 for quality management. These certifications demonstrate a commitment to producing reliable and consistent PCBs that meet or exceed industry standards.

Technological Capabilities:

The electronics industry is constantly advancing, and your PCB supplier should be equipped to handle the latest technologies. Inquire about the supplier’s technological capabilities, including their proficiency with advanced materials, surface finishes, and manufacturing processes. A forward-thinking supplier will be better positioned to support your project’s evolving needs.

Flexibility and Customization:

Every project is unique, and your PCB supplier should be capable of providing customized solutions to meet your specific requirements. Assess the supplier’s flexibility in accommodating design changes, prototype iterations, and production volume scaling. A supplier that can adapt to your project’s evolving needs will contribute to the success of your electronics venture.

Cost Considerations:

While quality is crucial, cost is also a significant factor in the decision-making process. Obtain detailed quotes from multiple suppliers and carefully assess the overall cost, including manufacturing, shipping, and any additional fees. Keep in mind that choosing the cheapest option may not always result in the best quality, so strike a balance between cost and quality that aligns with your project goals.

Communication and Support:

Effective communication is key to a successful partnership with your PCB supplier. Ensure that the supplier has a responsive and knowledgeable customer support team that can address your queries and concerns promptly. Clear communication channels contribute to a smoother collaboration and help prevent misunderstandings during the manufacturing process.