Copper Metallized Film: A Gleaming Innovation

Innovation is the driving force behind the continuous evolution of industries and technologies. One such remarkable innovation in the world of materials and packaging is Copper Metallized Film. This cutting-edge material is transforming various industries with its unique properties and versatility. In this blog post, we will delve into the fascinating world of Copper Metallized Film, exploring its applications, benefits, and the ways it is reshaping the future of packaging and beyond.

The Shining Advantages

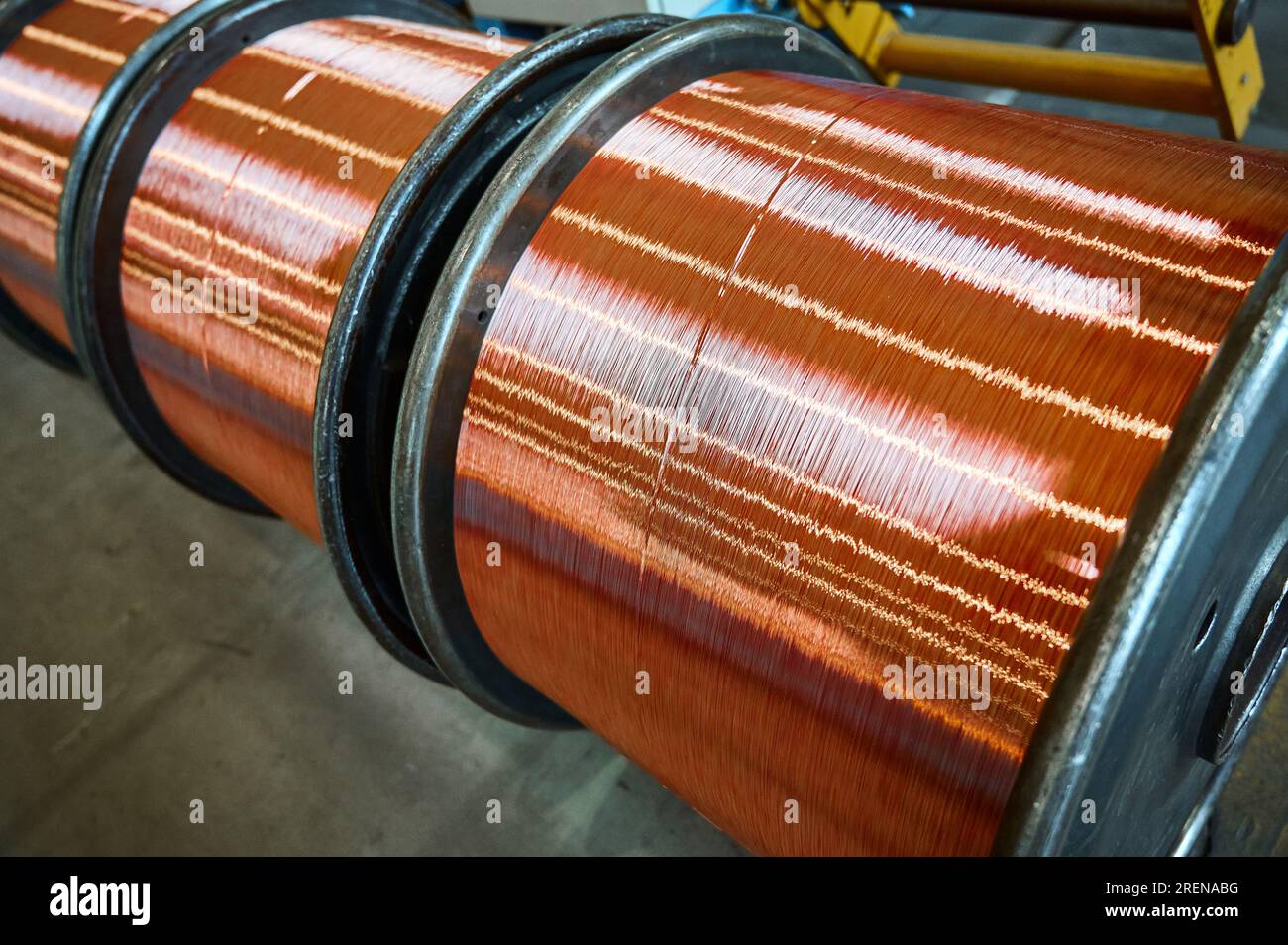

Copper Metallized Film is created by depositing a thin layer of copper onto a polymer film substrate, typically PET (Polyethylene Terephthalate). This process results in a film that boasts an array of impressive advantages:

- Superior Barrier Properties: Copper Metallized Film provides exceptional barrier properties, effectively blocking out moisture, oxygen, and UV radiation. This makes it an ideal choice for packaging sensitive products, such as food items and pharmaceuticals, ensuring extended shelf life and product integrity.

- Conductive Properties: The presence of copper allows the film to exhibit conductive properties. This is particularly valuable in applications like RFID (Radio-Frequency Identification) tags and flexible circuit boards, where electrical conductivity is essential.

- Aesthetic Appeal: The copper layer on the film gives it a distinct, high-end appearance. It can be customized to create eye-catching designs, making it popular in the packaging of luxury goods and cosmetics.

- Eco-Friendly: Copper Metallized Film is recyclable, making it an environmentally responsible choice. As sustainability becomes increasingly important, this material aligns with the global push for greener packaging solutions.

Applications Across Industries

The versatility of Copper Metallized Film opens up a world of possibilities across various industries:

- Food Packaging: With its excellent barrier properties, this film is commonly used for packaging perishable goods, snacks, and coffee. It helps maintain freshness and extends the product’s shelf life.

- Pharmaceuticals: Pharmaceuticals require packaging that safeguards their potency. Copper Metallized Film acts as a protective barrier, ensuring that medicines remain unaffected by external factors.

- Electronics: The film’s conductivity makes it an integral component in the production of flexible circuit boards, EMI shielding, and RFID tags. Its ability to transmit signals and protect sensitive electronic components is invaluable.

- Cosmetics: High-end cosmetic brands are increasingly opting for Copper Metallized Film for its luxurious appearance and its ability to preserve the quality of beauty products.

- Decorative Applications: Beyond its functional uses, the film is making waves in the interior design and automotive industries. It is being employed for decorative laminates, adding a touch of sophistication to various surfaces.

The Future of Packaging

In an era where sustainability and product integrity are paramount, Copper Metallized Film is set to play a significant role in shaping the future of packaging. Its ability to extend shelf life, protect products, and enhance visual appeal makes it a valuable asset for brands looking to stay ahead of the curve.

As technological advancements continue, we can expect further innovations in metallized films, potentially expanding their applications and benefits. The versatility and eco-friendly nature of Copper Metallized Film position it as a frontrunner in the quest for sustainable and effective packaging solutions.