Unleashing the Power of Ceramic PCBs: Revolutionizing Electronics

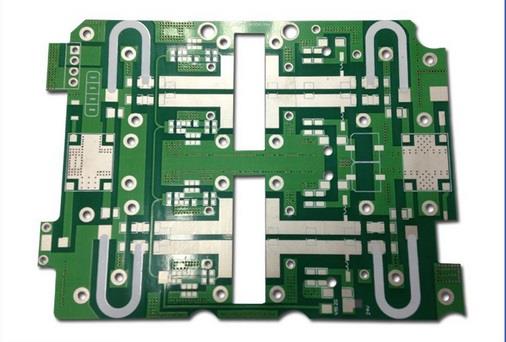

In the ever-evolving world of electronics, innovations that enhance performance, durability, and efficiency are always welcomed with open arms. One such groundbreaking technology that has been gaining prominence is Ceramic Printed Circuit Boards (PCBs). These specialized circuit boards, composed of ceramic materials, offer a myriad of advantages over traditional PCBs, making them a game-changer in various industries. In this blog post, we’ll explore the fascinating world of Ceramic PCBs and delve into the reasons behind their rising popularity.

Understanding Ceramic PCBs:

Ceramic PCBs, also known as ceramic substrates or ceramic circuit boards, are an advanced class of PCBs that employ ceramics as the base material instead of traditional substrates like fiberglass or epoxy. The most commonly used ceramic materials for PCBs include alumina (aluminum oxide) and aluminum nitride. These ceramics are chosen for their exceptional thermal conductivity, high mechanical strength, and excellent electrical insulating properties.

Key Advantages of Ceramic PCBs:

- Thermal Performance: One of the standout features of ceramic PCBs is their outstanding thermal conductivity. This characteristic allows for efficient dissipation of heat generated during electronic operations. This makes Ceramic PCBs ideal for applications where temperature management is critical, such as in high-power LED devices, power modules, and other heat-sensitive electronic components.

- High Frequency and RF Applications: Ceramic PCBs excel in high-frequency and radiofrequency (RF) applications. Their low dielectric constant and low signal loss make them suitable for wireless communication devices, radar systems, and other high-frequency applications where signal integrity is paramount.

- Mechanical Strength and Durability: Ceramics are inherently strong and rigid materials. Ceramic PCBs exhibit high mechanical strength, making them resistant to mechanical stress, vibration, and environmental factors. This durability is particularly advantageous in harsh operating conditions and demanding industrial environments.

- Miniaturization and High-Density Designs: The excellent dimensional stability of ceramic materials enables the creation of intricate and high-density circuit designs. This makes Ceramic PCBs a preferred choice in applications requiring miniaturization, such as in aerospace, medical devices, and wearable electronics.

- Chemical Resistance: Ceramics are highly resistant to chemicals, moisture, and corrosion. This property enhances the reliability and longevity of electronic devices, making Ceramic PCBs suitable for applications exposed to challenging environmental conditions.

Applications of Ceramic PCBs:

- LED Technology: Ceramic PCBs find extensive use in the LED lighting industry due to their superior thermal management capabilities. The efficient dissipation of heat ensures prolonged LED lifespan and consistent performance.

- Power Electronics: In power electronic devices like inverters and converters, where heat dissipation is critical, Ceramic PCBs contribute to enhanced reliability and efficiency.

- Aerospace and Defense: The aerospace and defense industries leverage Ceramic PCBs for their high reliability, durability, and ability to withstand extreme conditions. They are employed in radar systems, communication devices, and satellite components.

- Medical Devices: Medical electronics, including diagnostic equipment and implantable devices, benefit from the miniaturization and reliability provided by Ceramic PCBs.

Conclusion:

Ceramic PCBs represent a significant leap forward in the field of electronic components, offering a unique combination of thermal performance, mechanical strength, and chemical resistance. As technology continues to advance, the demand for these specialized circuit boards is expected to grow across various industries. The adoption of Ceramic PCBs not only enhances the performance and longevity of electronic devices but also opens up new possibilities for innovative designs in the ever-evolving landscape of electronics. The future undoubtedly holds exciting developments as Ceramic PCBs continue to play a pivotal role in shaping the next generation of electronic applications.