Exploring UV Curing Systems: Efficient Solutions for Industrial Applications

In the fast-paced world of industrial processes, innovation is the key to staying ahead. One such groundbreaking technology making waves is UV curing systems. These systems have redefined the landscape of various industries by offering efficient and high-performance solutions. Let’s embark on a journey to explore the brilliance of UV curing systems, their applications, and the transformative impact they bring to the table.

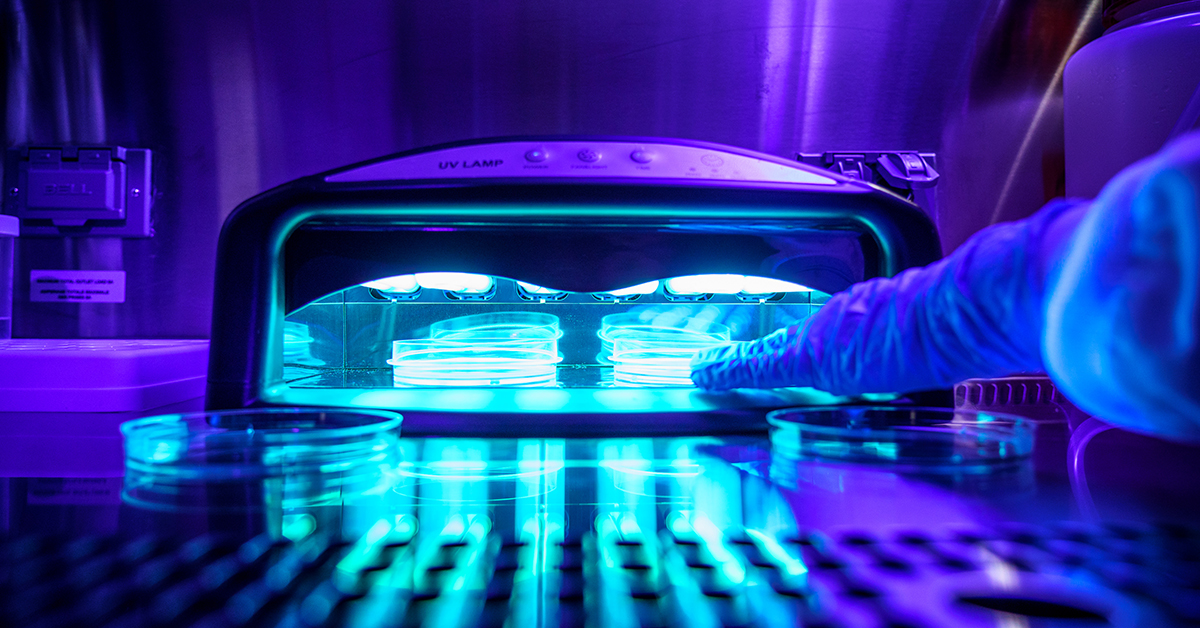

Understanding UV Curing Systems: UV curing systems utilize ultraviolet (UV) light to initiate a photochemical reaction that instantly cures or dries coatings, inks, adhesives, and other materials. Unlike traditional curing methods, UV curing is a rapid and energy-efficient process, leading to increased productivity and superior quality outcomes.

Applications Across Industries:

- Printing Industry: UV curing systems have revolutionized the printing industry by enabling quick and precise curing of inks on various substrates. From packaging materials to labels, UV curing ensures vibrant colors, improved adhesion, and a faster production cycle.

- Woodworking and Coating: In woodworking and coating applications, UV curing systems provide a durable and scratch-resistant finish. The instantaneous curing process eliminates the need for extended drying times, enhancing overall efficiency in the production of furniture, flooring, and other coated surfaces.

- Electronics Manufacturing: UV curing is widely employed in the electronics industry for bonding and encapsulation processes. The controlled and rapid curing of adhesives ensures the integrity of delicate electronic components while maintaining high throughput.

- Medical Device Manufacturing: The medical industry benefits from UV curing in the assembly of medical devices. Sterilizable and biocompatible adhesives cured by UV light ensure the reliability and safety of medical equipment.

Advantages of UV Curing Systems:

- Speed and Efficiency: UV curing is nearly instantaneous, significantly reducing production time and increasing overall efficiency.

- High-Quality Results: The precise control of UV curing results in a superior finish, improved adhesion, and enhanced product performance.

- Energy Efficiency: UV curing systems require less energy compared to traditional curing methods, contributing to a more sustainable manufacturing process.

- Versatility: UV curing can be applied to a wide range of materials, making it a versatile solution for diverse industries.

Future Trends: As technology continues to evolve, UV curing systems are expected to witness further advancements. From the development of more efficient UV light sources to enhanced curing formulations, the future holds exciting possibilities for this transformative technology.